PIM for manufacturing

Manufacturing companies are more exposed than other industries to immense price pressure, especially from Asian competitors. It is therefore a strange paradox that, although they continually invest in innovation in production itself, they usually invest very little in innovation in sales and communication with the market. Where can they find inspiration to make their routes to the customer as short and efficient as possible?

A trend today across all industries is digitalization, automation and cost reduction. This is even more true in manufacturing, where there is strong competition from Asian competitors, not just the local ones. It is necessary to be visible and to be an attractive B2B partner for as many distributors, resellers or end customers as possible. It is necessary to be able to compete on price and speed of response.

Despite this pressure, few manufacturing companies use modern software tools that can help them in sales and distribution. A lot of investments goes into innovation in manufacturing itself, but sales is still mostly handled by making phone calls and sending out emails with current catalogs.

As the suppliers of WisePorter, we know this situation from both sides. The manufacturers have a lot of work on their side to prepare the documentation and it takes weeks before a new feature or change reaches the customers. With orders based on old catalogs, a lot of people are then on the phone solving problems. They look for possible alternatives, additional production of missing pieces, or they cancel orders altogether if the required solution is no longer possible. All with an unpleasant impact on the client. When a person who has worked there for a long time and knows how things work leaves on the manufacturer or distributor side, the confusion is multiplied until a new person gets used to everything and can cope.

Distributors’ situation is also interesting. They often work with dozens or hundreds of manufacturers and resellers and often buy the same product from different sources. They always want to have up-to-date availability from everyone, perfect descriptions, pictures and videos on their own websites, simply to give their clients the best information to buy from them. On top of that, they need to have up-to-date pricing input, so that they sell at healthy margins while being price competitive. Achieving this with a large number of products in email correspondence with manufacturers and suppliers is not at all easy.

The solution is relatively simple. Just replace human work with software that automates it.

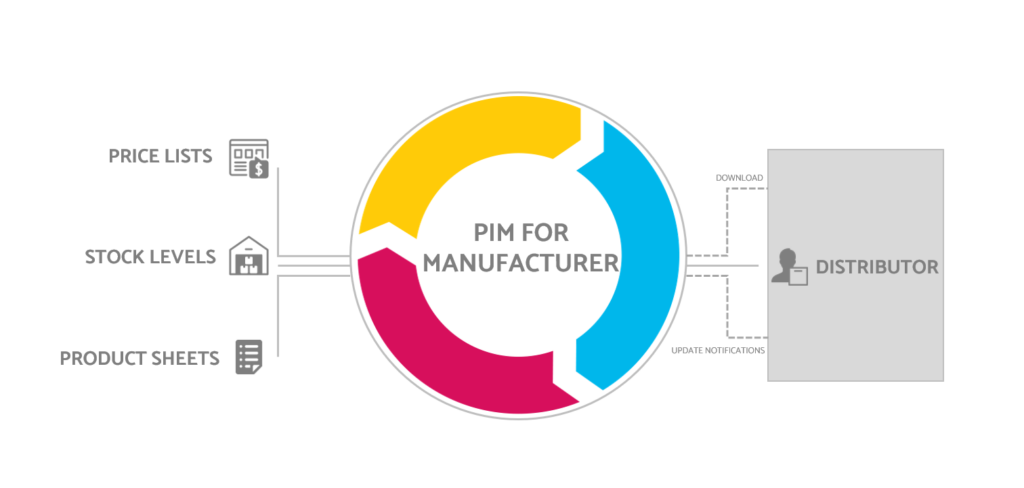

Whether we call it a Product Catalog, a PIM or a B2B portal for buyers, the idea is still the same. Everything distributors need to know about a manufacturer’s products is kept in one place:

- product lists, product lines, datasheets , parameters,

- stock availability and possible delivery times,

- marketing materials, images and videos that the distributor can download and use for promotion,

- and of course price lists, including promo events, discounts and volume bonuses.

Everything up-to-date, in one place. If the data already exists in the manufacturer’s CRM, ERP or another system, the product catalog automatically downloads it and merges it with other data so no one has to enter it a second time.

Everything is available at any time, to anyone who has access or is registered to receive changes. Everything is always up-to-date and valid.

It doesn’t matter if the manufacturer works with one or two distributors or with hundreds of companies. The cost of communicating with them is the same, there is no need to increase the number of people to take care of the business partners individually.

The key to success in the market is to have the widest possible potential for business cooperation at the lowest possible costs. And software that automates this area can be exactly the decisive factor that puts you on the cutting edge.